The ‘Swift Chair’ project was envisaged as a supercharged design sprint challenge to design, model and manufacture a chair that incorporates the ideals of ‘Lean Manufacturing’ all within 24 hours.

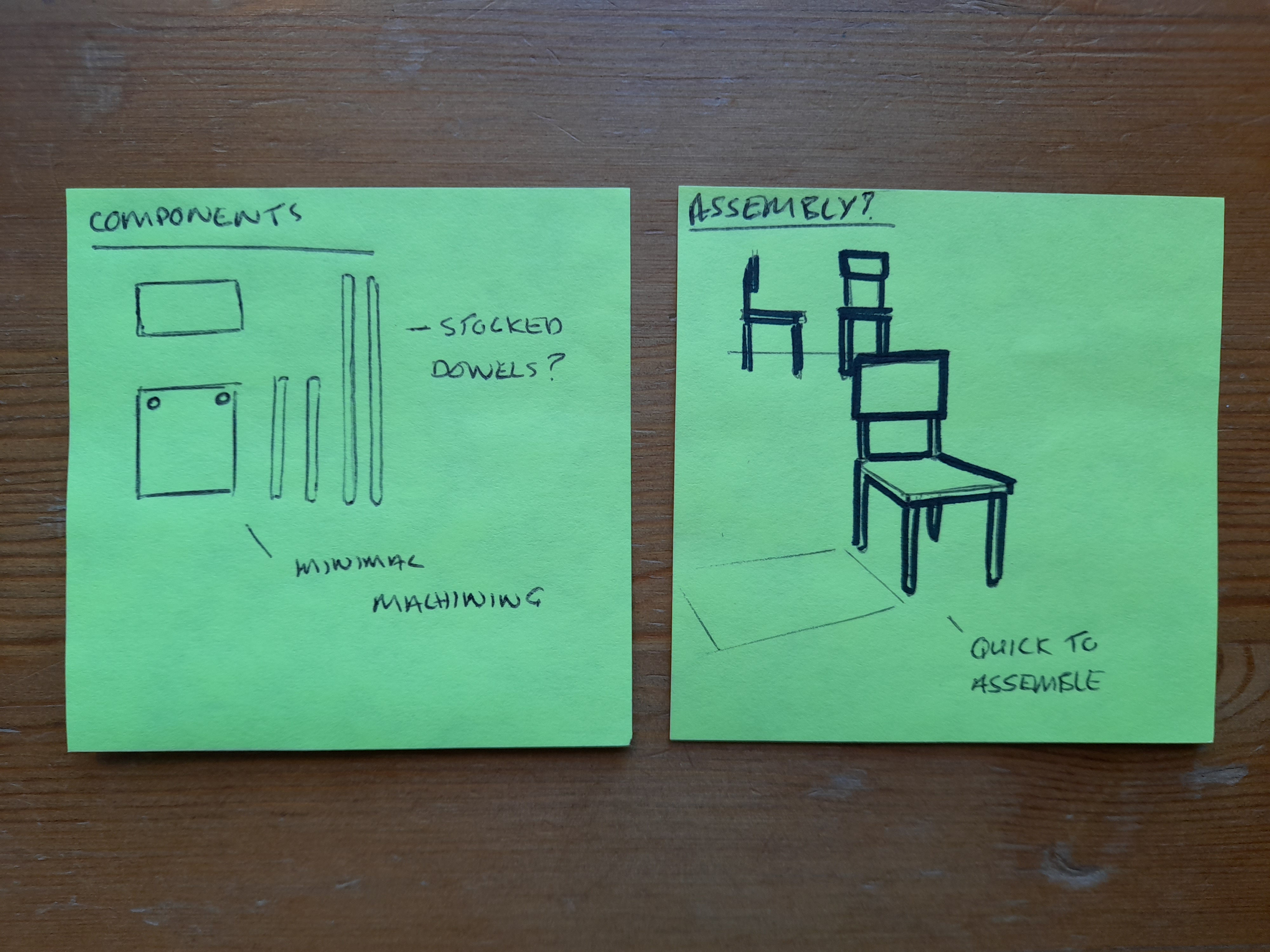

Lean manufacturing aims to reduce wastage in both material and time. Therefore the product needed to embrace the two following philosophies:

- Be quick to manufacture

- Be deliberately simple

This led to inital ideation and the concept to utlise stocked dowels and seat and backrests that require minimal machining time.

This concept was then modelled and visualised in Fusion 360, resulting in the prototype below.

The chair was designed with ease of manufacture and assembly in mind, and can be machined, fabricated and assembled in a matter of minutes.

The seat and backrest are 24mm birch ply, chosen for it’s high strength-to-weight ratio but also it’s compatability for CNC machining. The legs/frame are birch dowels, which can quickly be cut to required lengths with basic hand tools.

The GCODE was then produced and the first prototype components manufactured:

The time to manufacture these components was minimal, and the precise dowel slots allow the chair to be assembled using only a wood mallet, allowing the final prototype to be produced.

24 hours on from the initial idea, a fully-functional prototype was produced. This project was a great opportunity to embrace the ‘Just Create’ mentality and encourage quick design decisions and prototyping.

Linkedin: www.linkedin.com/in/edward-osborne-31b173209